Abstract

Carbon fibers are widely used as a reinforcement in composite materials because of their high specific strength and modulus. Current trends toward the development of carbon fibers have been driven in two directions; ultrahigh tensile strength fiber with a fairly high strain to failure (~2%), and ultrahigh modulus fiber with high thermal conductivity. Today, a number of ultrahigh strength polyacrylonitrile (PAN)-based (more than 6 GPa), and ultrahigh modulus pitch-based (more than 900 GPa) carbon fibers have been commercially available. In this study, the tensile strengths of PAN- and pitch-based carbon fibers have been investigated using a single filament tensile test at various gauge lengths ranging from 1 to 250 mm. Carbon fibers used in this study were ultrahigh strength PAN-based (T1000GB, IM600), a high strength PAN-based (T300), a high modulus PAN-based (M60JB), an ultrahigh modulus pitch-based (K13D), and a high ductility pitch-based (XN-05) carbon fibers. The statistical distributions of the tensile strength were characterized. It was found that the Weibull modulus and the average tensile strength increased with decreasing gauge length, a linear relation between the Weibull modulus, the average tensile strength and the gauge length was established on log–log scale. The results also clearly show that for PAN- and pitch-based carbon fibers, there is a linear relation between the Weibull modulus and the average tensile strength on log–log scale.

Similar content being viewed by others

Notes

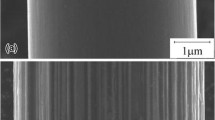

In the previous investigation, the cross-sections of the T1000GB and IM600 PAN-based, and the K13D and XN-05 pitch-based fibers are almost circular. The cross-sections of the T300 and M60JB PAN-based fibers are distorted oval. The T1000GB, IM600, T300, and M60JB PAN-based, and the XN-05 pitch-based fibers have particulate or granular morphology. The K13D pitch-based fiber has a sheet-like microstructure. The fractured surfaces of the T1000GB, IM600, T300, and M60JB PAN-based, and the XN-05 pitch-based carbon fibers show the initiation of failure from surface defects and a rough, rather poorly defined granular texture. However, the K13D pitch-based fiber obscures the initiation of failure and observes the crystallite sheets are a result of pull out at failure [4, 5].

In this testing procedure, all carbon fiber filaments did not shatter and all specimens were recovered. However, a few (10–20%) samples failed in the edge of the holder or outside of the gauge section. Fractures that initiated inside the gauge section of a fiber and the samples that recovered the fracture surfaces were counted.

References

Fitzer E (1989) Carbon 27(5):621. doi:10.1016/0008-6223(89)90197-8

Chand S (2000) J Mater Sci 35(6):1303. doi:10.1023/A:1004780301489

Rosa LG, Colella A, Anjinho CA (2006) Mater Sci Forum 514–516:672. doi:10.4028/www.scientific.net/MSF.514-516.672

Naito K, Tanaka Y, Yang JM, Kagawa Y (2008) Carbon 46(2):189. doi:10.1016/j.carbon.2007.11.001

Naito K, Tanaka Y, Yang JM, Kagawa Y (2009) J Am Ceram Soc 92(1):186. doi:10.1111/j.1551-2916.2008.02868.x

Johnson W (1985) In: Watt W, Perov BV (eds) Strong fibers, vol 1. Elsevier, Amsterdam, p 389

Thorne DJ (1974) Nature 248(5451):754. doi:10.1038/248754a0

Stoner EG, Edie DD, Durham SD (1994) J Mater Sci 29(24):6561. doi:10.1007/BF00354022

Padgett WJ, Durham SD, Mason AM (1995) J Compos Mater 29(14):1873. doi:10.1177/002199839502901405

Tagawa T, Miyata T (1997) Mat Sci Eng A Struct 238(2):336. doi:10.1016/S0921-5093(97)00454-1

Pickering KL, Murray TL (1999) Compos Part A Appl S 30(8):1017. doi:10.1016/S1359-835X(99)00003-2

Paiva MC, Bernardo CA, Nardin M (2000) Carbon 38(9):1323. doi:10.1016/S0008-6223(99)00266-3

Jones JB, Barr JB, Smith RE (1980) J Mater Sci 15(10):2455. doi:10.1007/BF00550747

Asloun EM, Donnet JB, Guilpain G, Nardin M, Schultz J (1989) J Mater Sci 24(10):3504. doi:10.1007/BF02385732

ASTM C1557-03 (2008) In: ASTM Annual Book of Standards, vol 15.01. American Society for Testing and Materials, West Conshohocken. doi:10.1520/C1557-03R08

Sung MG, Sassa K, Tagawa T, Miyata T, Ogawa H, Doyama M, Yamada S, Asai S (2002) Carbon 40(11):2013. doi:10.1016/S0008-6223(02)00059-3

Morimoto T, Nakagawa S, Ogihara S (2005) JSME Int J Series A 48(4):194. doi:10.1299/jsmea.48.194

Weibull W (1951) J Appl Mech 18:293

Lu CS, Danzer R, Fischer FD (2002) J Am Ceram Soc 85(6):1640. doi:10.1111/j.1151-2916.2002.tb00330.x

Danzer R (2006) J Eur Ceram Soc 26(15):3043. doi:10.1016/j.jeurceramsoc.2005.08.021

ASTM C1239-07 (2009) ASTM Annual Book of Standards, vol 15.01. American Society for Testing and Materials, West Conshohocken. doi:10.1520/C1239-07

Rosa LG, Figueiredo I (2010) Mater Sci Forum 636–637:1443. doi:10.4028/www.scientific.net/MSF.636-637.1443

Davies IJ (2004) J Mater Sci 39(4):1441. doi:10.1023/B:JMSC.0000013913.84004.cd

Absi J, Fournier P, Glandus JC (1999) J Mater Sci 34(6):1219. doi:10.1023/A:1004561023528

Trustrum K, Jayatilaka ADK (1979) J Mater Sci 14(5):1080. doi:10.1007/BF00561290

Pan N, Chen HC, Thompson J, Inglesby MK, Khatua S, Zhang XS, Zeronian SH (1997) J Mater Sci 32(10):2677. doi:10.1023/A:1018679207303

Wilson DM (1997) J Mater Sci 32(10):2535. doi:10.1023/A:1018538030985

Curtin WA (2000) J Compos Mater 34(15):1301. doi:10.1177/002199830003401503

Watson AS, Smith RL (1985) J Mater Sci 20(9):3260. doi:10.1007/BF00545193

Afferrante L, Ciavarella M, Valenza E (2006) Int J Solids Struct 43(17):5147. doi:10.1016/j.ijsolstr.2005.08.002

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naito, K., Yang, JM., Tanaka, Y. et al. The effect of gauge length on tensile strength and Weibull modulus of polyacrylonitrile (PAN)- and pitch-based carbon fibers. J Mater Sci 47, 632–642 (2012). https://doi.org/10.1007/s10853-011-5832-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5832-x